Paper Machinery

Paper Machinery

Pressurized Head Box

We “KEI” Can, Design, Manufacturing, supply and Commissioning of Complete New Head Boxes ( Open Type, Pressurized and Hydraulic Headboxs) with Best Quality and optimum price

-

Our “KEI” pressurized head box is the most flexible solution that allows operating in a wide range of consistency and speed up to 500 MPM for fourdrinier applications

-

Made out of High Quality Stainless steel Material

-

Special geometry of the bottom lip and the Micro adjustment of the top lip allow to obtain a very good basis weight profile

-

All the surfaces in contact with the stock are mirror polished with finishing grade of 0.2 µm to 0.4 µm

-

High Turbulence and Good Formation

-

Our Head Box will be supplied along with Foam Killing Shower and two side Edge deckles

Hydraulic Head Box

-

Our “ KEI ” Hydraulic head box is the most flexible solution that allows operating in a wide range of consistency and speed up to 300 MPM to 850 MPM for fourdrinier applications

-

PE – TANK having A Turbulence generating damping plate

-

Internal stock flow optimization due to an excellent distribution design

-

Slice opening can be manual-direct adjustment through high precision micro jacks

-

Uniform CM profile

-

Excellent formation quality

-

Compact design for easy installation on machine

Wire Part ( Fourdrinier / Multi Fourdrinier)

We “ KEI ” can offer the high efficient Wire part concept based on established design for all kind of paper grades

-

The length of the Fourdrinier wire table is designed for suit the Customer requirement Considering Paper quality and for furnish used.

-

These are designed with a frame of cantilever for quick and easy wire change.

-

All parts in Contact with stock or water are Stainless steel materials and Complete Stainless steel cladding construction.

Main parameters

-

Available Options : Single or Multi Layer Wires

-

Wire width : up to 5000 mm

-

Working Speed : up to 850m/min

Features

-

Better Formation

-

Better water drainage (Dewatering) system

Top Former

We “ KEI ” Can Provide Complete section, Upgrades and Enhancements top former unit

Features

-

Significant increase of production capacity

-

High flexibility for various grades

-

Optimum water removal and high drainage capacity

-

Improving of paper Two sidedness

-

Design and work safety are in compliance with EU Standards

Press Section

-

We “ KEI ” Design the Press Section considering for best dryness and bulk.

-

Press section Ranging from Straight Thro Press, Bi-Nip Press, Combi Bi-Nip Press, Tri Nip Press, Jumbo press (Incl Cantilever ) with focus on the requirement of Paper, Board or specialty Papers.

-

Heavy Duty Framings with Hydraulic System suitable for Nip Load of 450KN/m and Roll Diameter up to 1500mm.

-

Expansions and modernizations of existing sections.

Size Press Section

-

Puddle type size press is designed to increase the surface strength of paper web. Other benefits also includes.

-

Reduced dusting tendency, increased stiffness and reduced air-permeability.

-

Improve strength, surface smoothness in writing / printing / Media / Kraft / board Add pigments to the surface of the web.

-

Rigid framings with Hydraulic or pneumatic loading system.

-

Size kitchen equipments also can be provided.

-

Complete Sections, Upgrades and Enhancements.

Dryer Section

-

We “ KEI ” Design and Supply of dryer section designed for best drying efficiency and uniform drying.

-

Heavy Duty Dryer Frames are made out of MS Fabricated and Cast iron suitable to drying cylinders dia upto 1800 mm.

-

Dryer Section can be provided with the entire steam and condensate system and lubrication.

-

High efficiency doctoring system can be provided for smooth operation.

-

Converting Open Gear / Closed Gear Drive System into Silent drive system (Multidrives)

-

Expansions and modernizations of existing dryer sections.

Calendar Section

-

Calender is designed to make the paper surface extra smooth and glossy and Gives it a more uniform thickness to the final product.

-

Heavy Duty framings with hydraulic or pneumatic loading system.

-

Simple and easy to operate.

-

Auto web feeding.

-

Back to Back arrangements can be supplied if both surfaces are to be smoothed.

-

Soft Nip Calender Can also be provided where the matting roll has a soft cover to improve web contact uniformity against the heated roll.

POPE SECTION

-

We “ KEI ” manufacture a wide range of Pope Reel is well known for its sturdy construction and high efficiency, reel face up to 5500mm, reel drum diameter: 800mm - 1200mm

-

Robust design framings with Hydraulic or Pneumatic system to produce homogeneous jumbo rolls with minimum losses

-

Flexible design allowing gradual accessories installation until full automation increasing efficiency and safety

-

Our Pope section Having options of “ Reel Spool Storage with Loading Arms ” , “ Auto spool Loading System” , “Jumbo roll weighing station ” and “Extended Rails to unwinder equipped with all necessary devices to ensure operators safety

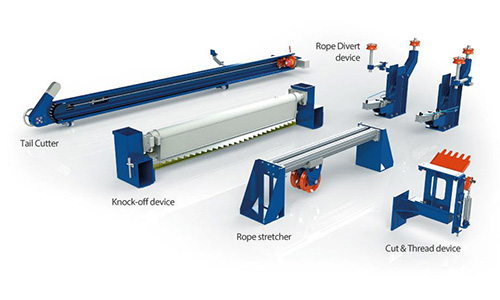

TAIL THREADING SYSTEM

-

We “ KEI ” Design and Supply of Wetend / Dryend Tail Cutter, Rope Feeding systems requirements

Benefits

-

Allow a safe operation during tail threading

-

Reduction in Losses

-

Increases machine efficiency